SCHWÖRER BATHROOM PODS

Each Schwörer bathroom pod is designed and produced to your specific wishes and ideas, with our high level of technical know-how.

Our bathroom pods are self-supporting modules, which can be installed easily and problem-free using a suitable fixed or mobile crane.

The maximum dimensions of our bathroom pods are determined by the transport dimensions. The optimum transport width is 2.45 m (incl. external installations) and the optimum transport height is 2.70 m. Clear room heights of 2.40 m maximum can thus be realised.

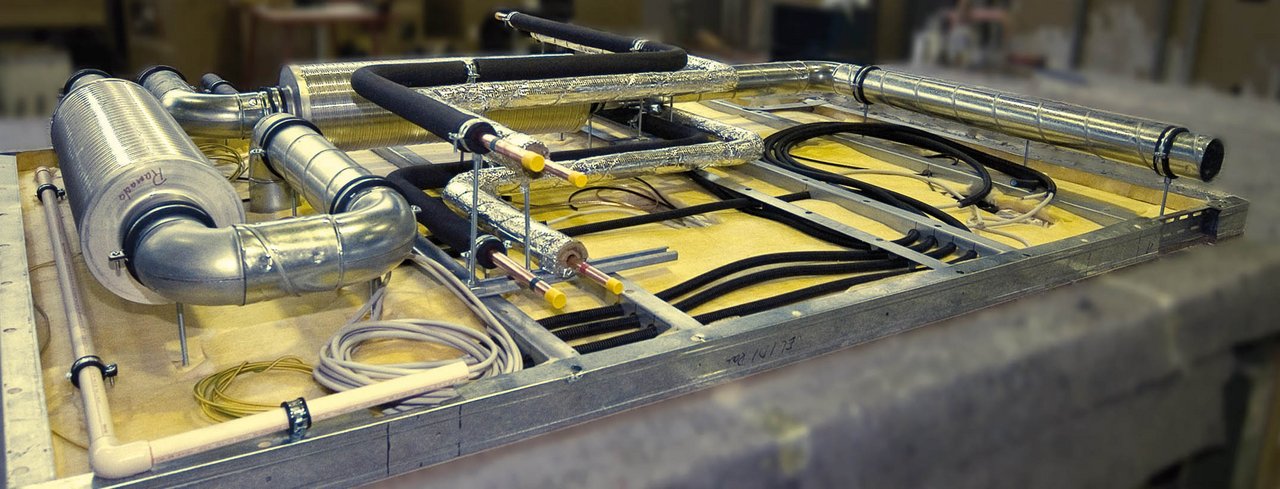

Designed to your product specifications, our heating – sanitary – ventilation designers add a large number of additional technologies, which complete our bathroom pods and are carried out directly in our Berlin production plant.

From the shut-off device, kitchen connections, heating circuit distributor, hot water station, apartment electrical sub-distribution board through to the complete shaft installation module for the risers, we supply you with a complete solution, which reduces your construction site work and risks.

With this comprehensive package of work and services, we fulfil our pledge of “Design, execution and warranty from a single source” to a particular degree.

Floor

A differentiation is made between steel-reinforced concrete floors (approx. 160 kg/m²) as the standard design and steel section floors (approx. 60 kg/m²) as a special design.

The concrete floor consists of a steel frame surround, which is strengthened with reinforced concrete.

The steel frame floor consists of a hollow section construction with a 16 mm thick building board as the substrate. The wall cavities are insulated using 40 mm mineral fibre insulating boards.

Wall

The walls consist of a construction of sheet steel support sections and sheathing on the bathroom side made using a building board. The wall cavities are insulated using 40 mm mineral fibre insulating boards. The sheathing with gypsum boards in the room is usually carried out on-site by the client. We can also carry out this work on request.

Ceiling

Our ceiling construction consists of a building board, 15 or 16 mm, installed under a support structure made of sheet steel sections.

The underside of the ceiling is primed, smoothed and a high-quality paint coat is applied in the factory.